Products description

Description

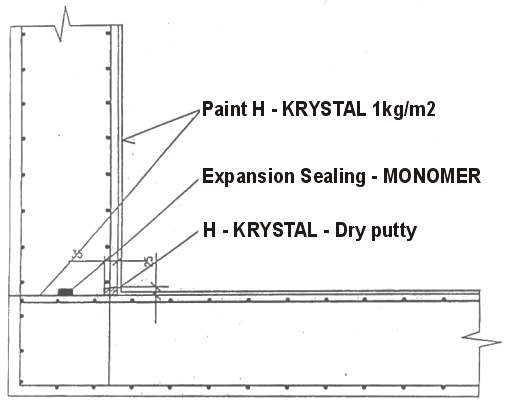

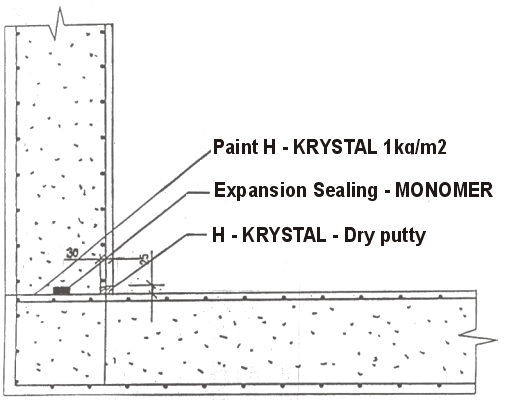

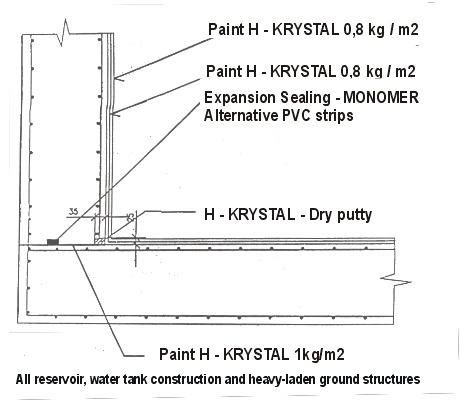

Painting and spraying of concrete metal during the initial construction is possible from the interior or the exterior, or a combination of both applications. Thereby directing and placing the dry putty using a high compression mallet made from H - Krystal and water (6:1), for the space between the wall and the ground.

With the pre-foundation boards we can do the crystallization spraying before pouring the foundation for the groundwork concrete at least 3 to the maximum of 24 hours ahead of time. Instead of expansive tamping on the work joints we can use an internal PVC strip. The concrete can be used as all kinds of construction concrete.

The Hydra system

Using the H - Krystal M additives in all construction one achieves detailed work processed joints for the foundation. Work processed joint crystallization and water insulation H - Krystal.

Using concrete metal is common in construction, for better control over solidification add UNIFILL 12mm polypropylene fibers in the amount of 0.6 – 0.9 kg-1m³

The Hydra system

In high water or chemical heavy-laden construction, detail treatment working joints and the foundations using water insulation crystallization H - Krystal.

The Hydra system

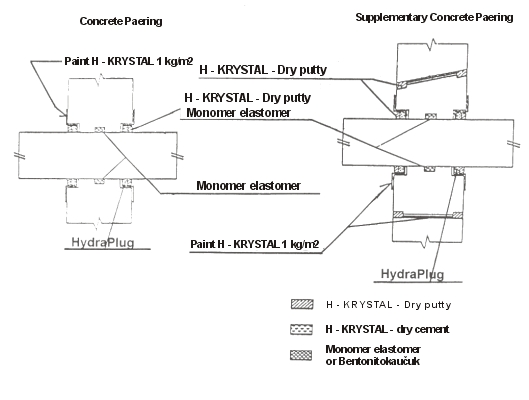

Detailed work processed gripe in previous concrete metal constructions of new structures using the crystallization H - Krystal, elastomer =elastic monomers, or betonite + rubber= water stoppers.

This is the overall project detail. How to process:

- Elastomer materials are mounted to the pipeline before pouring concrete using a special glue in the cartouche.

- On the pre-groove surface or supplementary stub of the tightening groove of the working gripe dab on one layer.

- After implementing H - Krystal we seal the trough about halfway with the sealing Hydraplug against running water and we finish sealing the trough using the dry putty made from H-Krystal and water (6:1).

What is deep or complex Crystallization?

Concrete + H-Krystal = Impermeability of concrete

Not interchangeable with the penetrating solution and it’s sequential crystallization below the surface.

The problem of the impermeability of concrete is as old as concrete itself. If concrete constructions were impermeable, there would be lower costs for insulation, which would

mean an easier construction, as well as a much larger time range for the rehabilitation of concrete. However, we have before us concrete rock combined with a porous structure that enables the passing of liquids and gases. This continuity for various chemicals is very dangerous, especially in metal concrete, because it impairs the alkaline reinforcement protection and changes the components of the concrete into other dangerous concrete compounds.

There are two ways to reach concrete impermeability. By the application of ingredients into the fresh concrete mix or by the application of special materials, thereby filling the capillaries of the already hardened concrete surface. Both options can be fulfilled using the product H-Krystal, without any negative influence on the mechanical attributes / characteristics of the concrete.

It is necessary to point out that in this process, there is 2 times more water in the mixture than that which is necessary for the hydration of cement. This water stays in the concrete even after hardening, evaporating very slowly, and may stay in the concrete for decades. Otherwise, water gets into concrete in many ways. In underground structures where there is a lot of pressure, water enters the concrete forcefully.

The application of a substance, which completely uses up the water that is suspended in the capillary system and the residual products of hydration to reactions in the compounds, in the end forms crystals and fills in the capillary system. This is the case with H-Krystal, which is a catalyst to concrete and sand. In the capillary environment, H-Krystal with the help of water initiates the growth of crystals and thus safeguards the mass imperviousness of the concrete. In the presence of water and temperatures above +5 °C, the Krystals grow to be the size of 350 mm or more in the structure.

The growth of the Krystal stops after extracting the water from the capillaries. Concrete maintains its ability to breath but is closed off from any incoming water. Thus the chemical compounds in a pore concrete system are only harmful in the presence of water, which no longer has access to the capillaries. If we recognize this about the revolutionary watertight concrete, where only the concrete’s outside vacant surface is exposed to aggression, then construction can offer resistance for a much longer time than if it is damaged by it's aggressive surroundings.

Therefore this technology isn’t damaged by construction work and completely replaces folium and asphalt insulation. It protects from corrosive armature, it calls off hydrostatic pressure and aggressive waters, it guards against freezing temperatures, keeps CO2 from seeping through, guards against corrosive of salt defrosting and sulphates, calls off petroleum products, stops carbonate and it isn't toxic!

The cement is 100% water insulated

Use: Like the final insulation for:

Can be used for anyplace from all residential constructions, sterile constructions, reservoir drains, foundation constructions, terraces, flat roofs, weirs and dams, shafts, supporting walls, in plain and metal concrete, and in the rehabilitation of concrete constructions. Finally, it can also be used to stop dampness from seeping through in places with damaged or missing folium insulation, or as a secondary safety.

This crystallization method has been in use and on the market since 1965.